搜索

To effectively ensure laboratory safety on campus, prevent safety accidents, and maintain safe and stable operations during the May Day holiday, on April 30, the Zhangjiang Institute for Advanced Study (ZIAS) organized a comprehensive pre-holiday safety inspection. The inspection was led by Deputy Dean Zhao Degang. A special inspection team was formed by the Campus Operations and Maintenance Office and the Zhangjiang Security Section, conducting thorough and all-encompassing inspections in key areas of the campus to identify and eliminate potential safety hazards.

Focusing on Key Areas and Identifying Hazards — Strict Laboratory Safety Control

The inspection team treated laboratories as the core focus of this safety inspection, concentrating on hazardous chemical management, operation of special equipment, electrical and gas safety, usage of experimental batteries and heating devices, disposal of hazardous waste, and the availability of fire safety equipment. The team emphasized that all centers/platforms and laboratories must strengthen their sense of responsibility, strictly implement daily management systems, ensure standardized and safe operation, and resolutely prevent all types of safety incidents.

Targeted Measures and Standardized Operations — Strict Risk Control for Holiday Experiments

With regard to experiment arrangements during the May Day holiday, the inspection team made clear requirements: for laboratories without scheduled experimental tasks, all water, electricity, and gas supplies must be completely shut off before the holiday, and doors and windows must be closed to fully achieve “cutting off and locking down” in order to eliminate potential hazards; for laboratories that must remain operational during the holiday, detailed experimental plans must be formulated, all standard operating procedures must be strictly followed, and individual protective measures must be thoroughly implemented to ensure controllable safety.

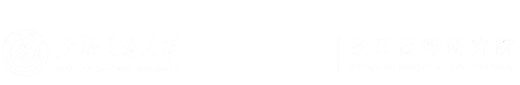

Full Coverage, No Blind Spots — Thorough Risk Elimination Across Campus

Beyond laboratories, the inspection team also conducted full-coverage safety inspections in key campus areas such as the cafeteria, chiller plant, boiler room, and substation. The focus was on the functioning of fire safety equipment, routine work logs, the condition of electrical appliances, and food hygiene management, aiming to eliminate all potential safety risks.

Strengthened On-Duty System and Accountability — Quick Emergency Response During Holidays

The inspection team pointed out that safety management during holidays leaves no room for laxity. All laboratories must strictly enforce the on-duty patrol system to ensure that any emergency can be promptly responded to, handled swiftly and scientifically, and reported in a timely manner to the institute, achieving closed-loop safety management.

Safety is the prerequisite for scientific and technological innovation, and stability is the foundation for sustainable development. This comprehensive pre-May Day safety inspection was not only a full health check-up of the campus’s current operational status but also a strong demonstration of ZIAS’s firm commitment to the philosophy of “safety first, prevention foremost, and responsibility to the individual.” ZIAS will continue to shoulder safety management responsibilities with a strong sense of mission and accountability, improve long-term mechanisms, and build a safer, more standardized, and sustainable research environment on campus.

Address:No.1308 Keyuan Road, Pudong District, Shanghai

Address:No.1308 Keyuan Road, Pudong District, Shanghai Phone:86-21-54740000

Phone:86-21-54740000 E-mail:zias@sjtu.edu.cn

E-mail:zias@sjtu.edu.cn