搜索

Recently, Professor Zhou Han from the Center for Future Materials Innovation at the Zhangjiang Advanced Research Institute of Shanghai Jiao Tong University, in collaboration with Academician Zhang Di from the State Key Laboratory of Metal Matrix Composites at the School of Materials Science and Engineering, Shanghai Jiao Tong University, proposed an innovative “dual-function photonic battery” inspired by the color-changing properties of cephalopod skin. This silicon-based device integrates lithium-ion electrochemical reactions to dynamically regulate infrared emissivity through reversible lithiation/delithiation processes. It simultaneously achieves radiative cooling and solar heating capabilities while offering high-capacity electrical energy storage. Simulation analysis indicates that applying this material to buildings could significantly reduce energy consumption by up to 18.4% and cut CO₂ emissions by 124.1 tons annually, offering a novel approach for developing energy-efficient, electrically driven dynamic materials.

Amidst the global energy crisis and frequent extreme weather events, building energy consumption has become a major contributor to worldwide energy use. Simultaneously, power outages caused by climate change and aging power grids are worsening, disrupting normal building operations. Achieving intelligent thermal management and energy self-sufficiency in buildings has become a critical challenge for green, low-carbon construction development.

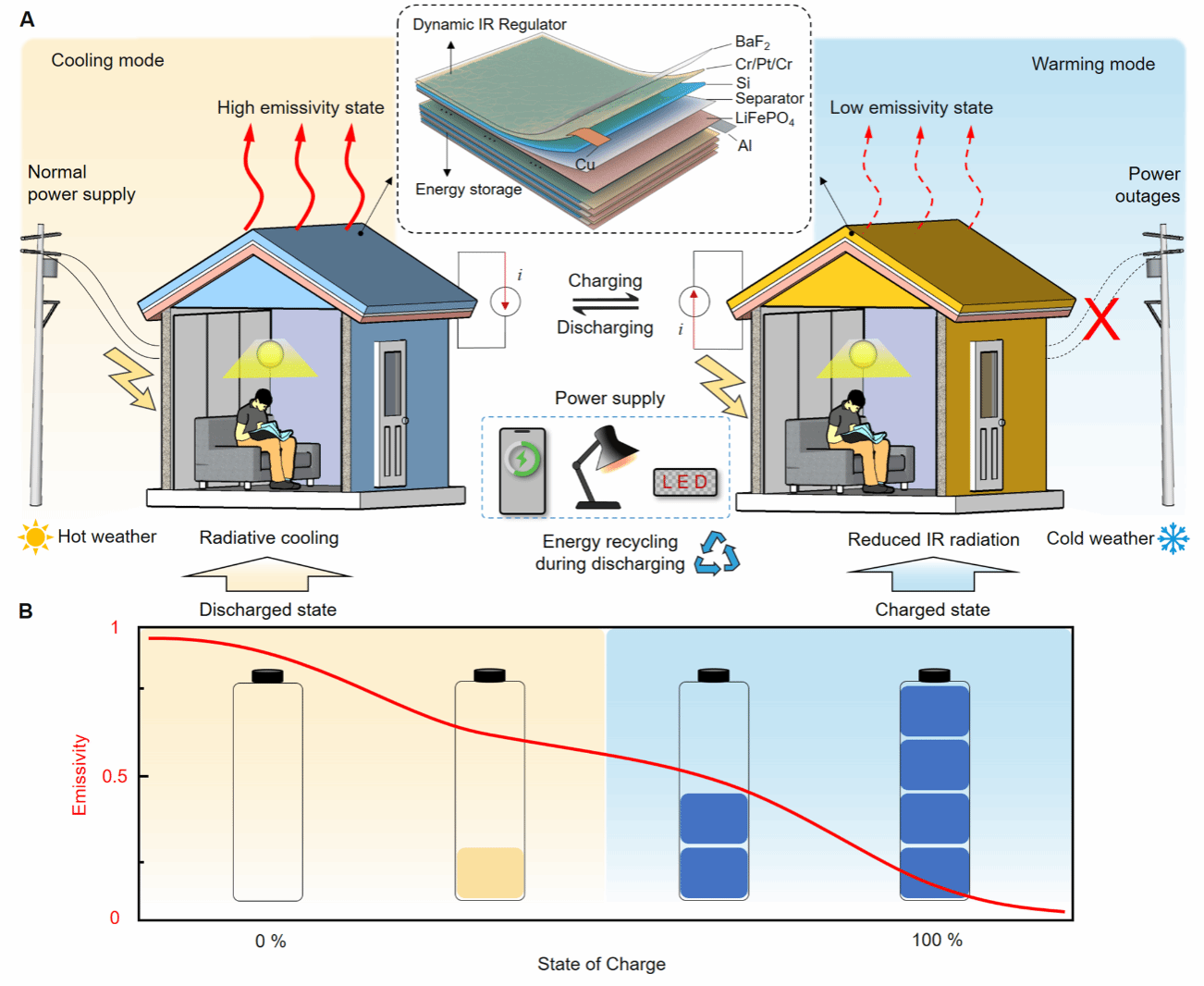

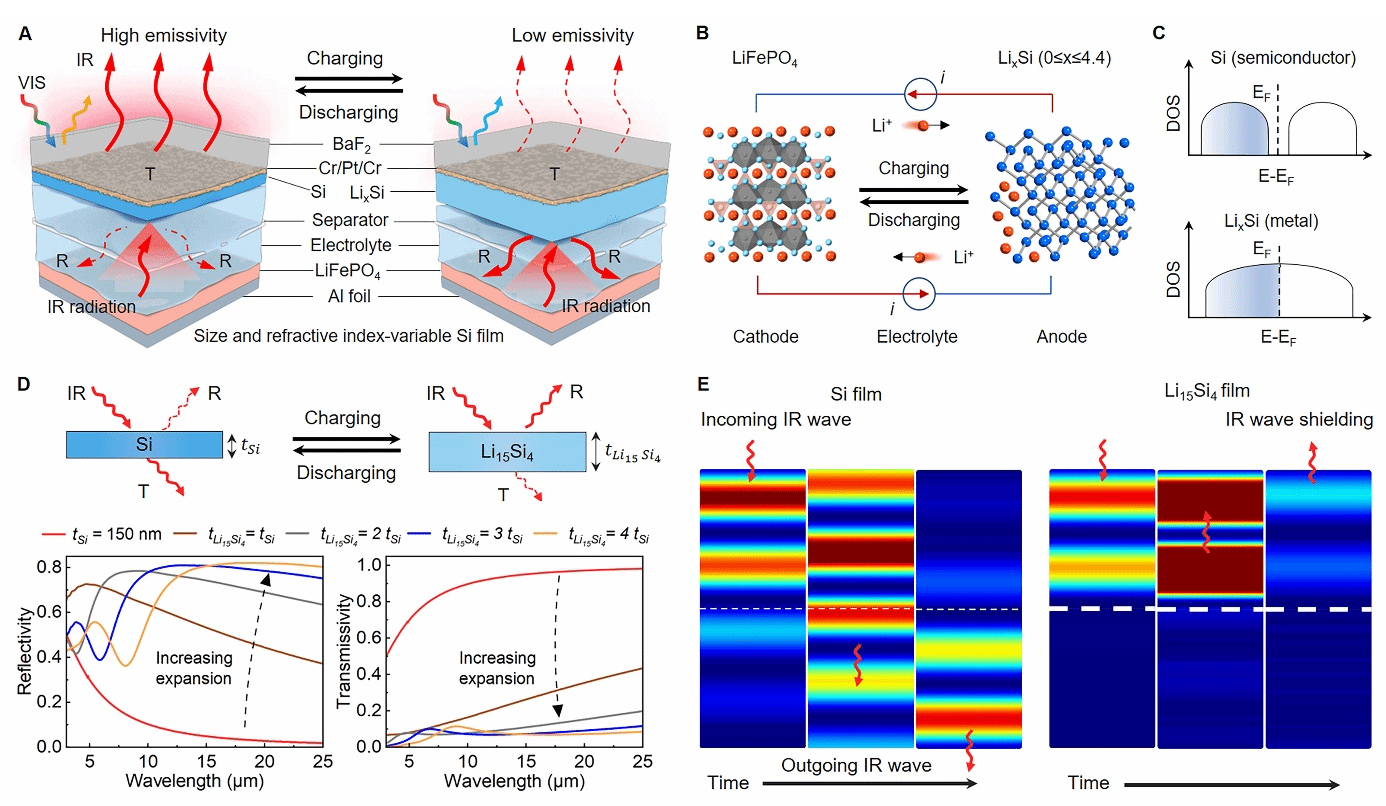

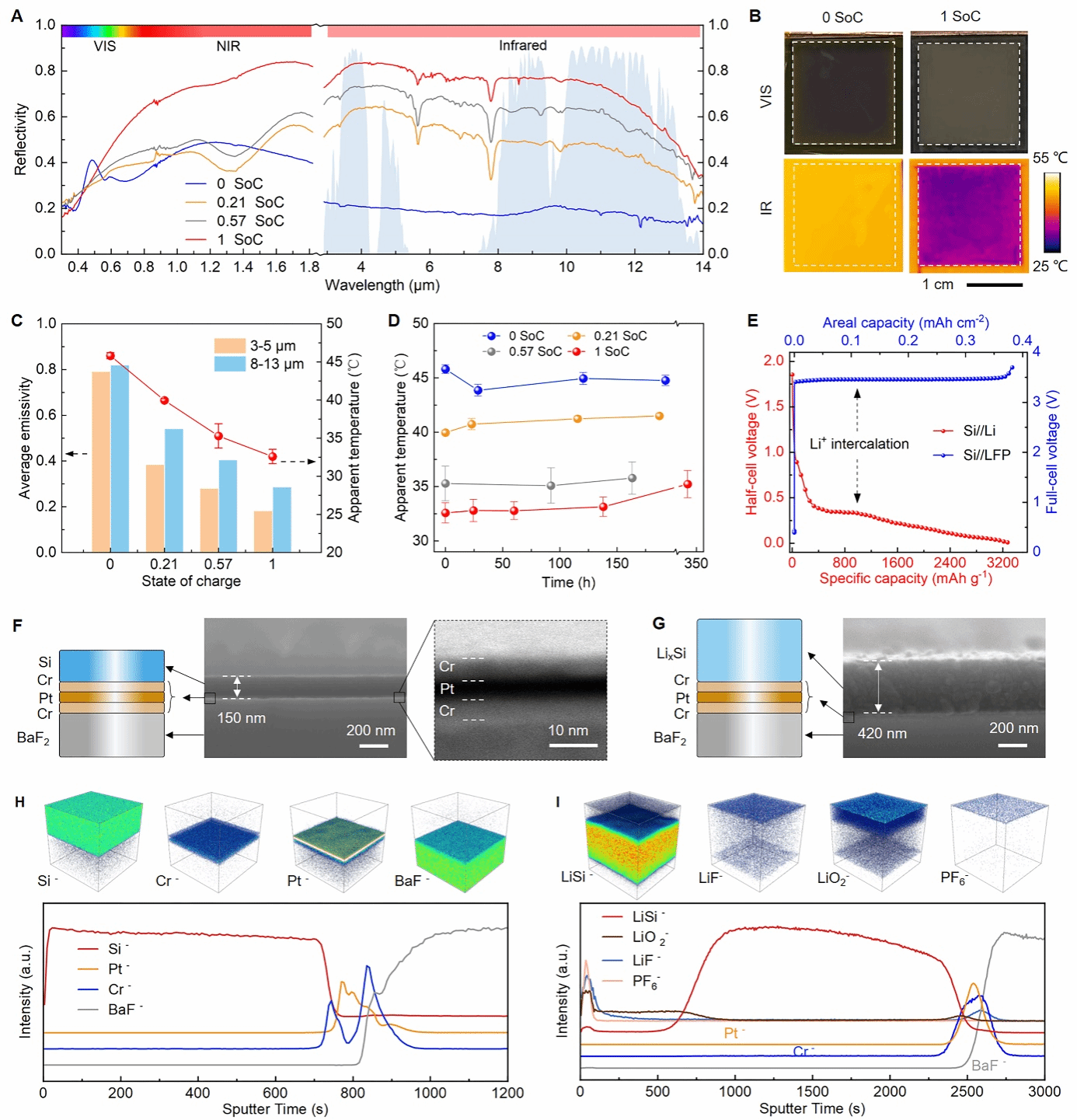

Addressing the limitations of existing thermal management materials—which offer single-functionality and cannot simultaneously regulate temperature and supply energy—this study draws inspiration from the color-changing properties of cephalopod skin. It proposes a novel photonic battery (SEP) that integrates dynamic thermal management with energy storage. The design principle and fabrication process are illustrated in Figure 1. The device achieves reversible lithium-ion insertion/extraction, inducing phase transitions and dimensional changes in silicon material to modulate its infrared emissivity. This enables radiative cooling in summer and thermal insulation/heating in winter while providing efficient electrical energy storage and power supply capabilities. Its structure and optical regulation properties are illustrated in Figure 2. The lithiumation process in SEP devices significantly enhances silicon layer reflectivity, achieving a controllable reflectance range up to 0.67 in the mid-to-far infrared band (8–13 μm). Thermal management and energy storage performance are illustrated in Figure 3. SEP devices enable controllable infrared emissivity adjustment across different charge/discharge states: exhibiting high emissivity (active cooling) during discharge and low emissivity (thermal insulation/heating) during charging. Concurrently, the device delivers an energy storage capacity of up to 3271 mAh/g, ensuring stable power supply for electronic devices during power outages. Global energy consumption simulations (Figure 4) demonstrate that when applied to building facades, SEP devices achieve an average annual building energy savings of 18.4% across diverse climate zones, reducing CO₂ emissions by 124.1 tons per year. This highlights broad prospects for energy conservation, emissions reduction, and green building applications. Future deployment is anticipated in building energy self-sufficiency, smart energy management, and extreme environment protection.

The photonic battery proposed in this study pioneers a new direction for thermal management materials, achieving a multifunctional integrated design that combines heat regulation with energy supply. This technology can be applied not only to smart building envelopes for active temperature control and reduced HVAC energy consumption but also serves as an emergency power source, enhancing a building's energy self-sufficiency in extreme environments. Future applications are anticipated in green energy-efficient buildings, extreme environment protection, and smart city energy management, contributing novel material solutions toward carbon neutrality goals.

The research, titled “Dual-functional photonic battery enabling dynamic radiative thermal management and power supply,” is published in Advanced Materials. Dr. Wang Pan from Shanghai Jiao Tong University is the first author. The study received funding from the National Natural Science Foundation of China and the Shanghai Science and Technology Development Fund.

Original link: https://advanced.onlinelibrary.wiley.com/doi/full/10.1002/adma.202412328

Figure 1: Conceptual schematic of SEP devices for dynamic energy-saving buildings and their application in energy storage and recycling. (a) Schematic illustration of SEP devices integrated into building roofs or exterior walls, enabling on-demand thermal regulation and power supply for buildings. The top illustration depicts a multi-layered stacked cell structure where upper-layer SEP devices primarily serve dynamic thermal regulation, while lower-layer SEP devices function as energy storage units to enhance overall capacity, enabling comprehensive utilization as building envelope components. Note that SEP devices in a charged state exhibit low infrared emissivity to supply electricity to appliances; switching to a high-emissivity state enables energy recovery and reuse (bottom illustration). (b) Schematic illustrating the relationship between infrared emissivity and the state of charge (SoC) in SEP devices.

Figure 2: Design principle and theoretical analysis of the SEP device. (a) Schematic structure of the SEP device in the discharged state (left) and charged state (right). The device consists of a BaF₂ protective layer, a multispectral transparent Cr/Pt/Cr thin-film electrode, a Si thin film (negative electrode), an electrolyte-containing separator, and an aluminum foil coated with LiFePO₄ (positive electrode). (b) Schematic of lithium ion (Li⁺) intercalation and deintercalation within the Si film. During charging, Li⁺ intercalates into the Si film, increasing its thickness and altering its refractive index, thereby suppressing infrared emissivity; the reverse process occurs during discharging. (c) Schematic of the density of states (DOS) for Si and the Li-Si alloy. (d) Schematic of infrared light propagation on Si film and fully lithiated Li₁₅Si₄ film (top), and theoretical calculations of reflectance (R) and transmittance (T) for 150 nm thick Si film with different thicknesses of Li₁₅Si₄ film (bottom). Li₁₅Si₄ film thicknesses are 150, 300, 450, and 600 nm, representing 1-, 2-, 3-, and 4-fold volume expansion of the Si film after lithiation. (e) Characteristic plots of the dynamic electric field distribution (|E|²) for a 150 nm thick Si film (left) and a 350 nm thick Li₁₅Si₄ film (right) when irradiated with infrared light at a wavelength of 10 μm.

Figure 3: Performance characteristics and structural deformation visualization of SEP devices before and after lithiation. (a) Reflectance test results of SEP devices under different states of charge (SoC) across visible, near-infrared, and infrared bands, showing an overall trend of increasing reflectance with rising SoC. The SEP device used in this experiment measures 2.5 cm × 2.5 cm. (b) Visible light (VIS) and long-wave infrared (LWIR) images of the same SEP device at different SoCs, with the white dashed box indicating the device's active area. (c) Relationship between the average infrared emissivity and apparent temperature of the SEP device in the LWIR band versus SoC. (d) Non-volatile test results of the SEP device under different lithiation states (SoC). (e) Typical voltage-capacity curves of the SEP device (Si//LFP full cell) and a half-cell based on SEP material (Si//Li), demonstrating the Li⁺ insertion process. (f) Schematic cross-sectional structure (left), scanning electron microscopy (SEM) image (middle), and transmission electron microscopy (TEM) image (right) of the SEP material device in the discharged state (Si/Cr/Pt/Cr/BaF₂). (g) Cross-sectional SEM image of SEP material in the charged state (LixSi/Cr/Pt/Cr/BaF₂). (h, i) Time-of-flight secondary ion mass spectrometry (TOF-SIMS) depth profiling of SEP material during discharge (h) and charging (i), showing the distribution of multiple characteristic ion fragments. Above: Three-dimensional spatial reconstruction images of representative ions. Li₂O and LiF generate LiO₂⁻ and LiF₂⁻ ion signals, respectively, while LixPFy and residual lithium salts produce PF₆⁻ ion signals.

Figure 4: Applications of SEP Devices in Building Energy Conservation and Power Supply. (a) Global distribution map of SEP device energy-saving potential, based on global climate data and using a standard building as reference. (b) Annual energy savings, energy efficiency improvement rate, and carbon reduction effects calculated using a typical office building model and meteorological data from different cities (Data Source 1#). (c) Comparison of annual energy savings and energy efficiency improvement rates for SEP devices under different installation methods. (d) Schematic of an energy supply system built with SEP devices, where a DC/DC converter regulates the output voltage to meet electrical equipment demands. An ammeter-voltmeter records output current and voltage to calculate the electrical energy converted by SEP devices. (e) Physical image of experimentally fabricated large-area arrayed SEP devices, with individual device dimensions of 5 cm × 5 cm. (f-h) Demonstration of SEP devices powering a display screen (f), a small fan (g), and a white 3 V LED (h, inset). The display and LED are powered by a 3 cm × 3 cm SEP device, while the fan is powered by a 5 cm × 5 cm device. Current and voltage changes during LED operation are simultaneously recorded. (i) Calculated single-household energy storage capacity and power supply duration for SEP devices with varying layer counts under 71.6% conversion efficiency (RE). Higher layer counts enable longer single-household power supply duration. (j) Performance comparison between SEP devices and other electrochromic devices.

Author: Zhou Han Team

Contributing Unit: Center for Future Materials Innovation

Address:No.1308 Keyuan Road, Pudong District, Shanghai

Address:No.1308 Keyuan Road, Pudong District, Shanghai Phone:86-21-54740000

Phone:86-21-54740000 E-mail:zias@sjtu.edu.cn

E-mail:zias@sjtu.edu.cn